Calculate Net, Gross, and Tare Weight in Shipping: Read This Review Before You Buy

Ever been slapped with unexpected shipping fees, or had your shipment held up at customs due to inaccurate weight info? If you’re importing or exporting goods, getting your weights right isn’t just smart—it’s essential.

Shipping costs, freight bookings, customs paperwork, and even tax calculations depend on accurate weight measurements.

This guide will teach you how to calculate net, gross, and tare weight in shipping step-by-step.

You’ll learn the exact formulas, where to get the data, and how each weight affects your bottom line. Plus, you’ll get a crash course in common mistakes to avoid.

Before you book your next freight—Read This Review Before You Buy or Ship.

Table of Contents

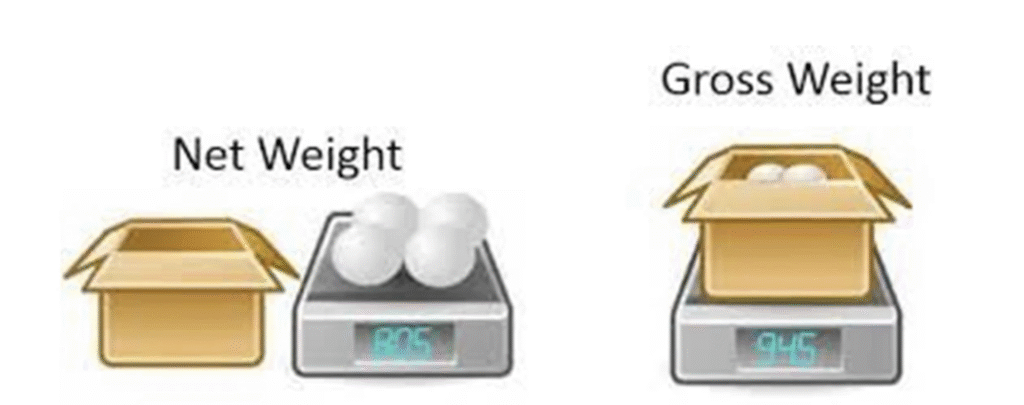

What Is Net, Gross, and Tare Weight?

To keep things simple, let’s use a real-world analogy: think of a can of soda.

- Net Weight = the actual soda inside the can

- Tare Weight = the empty can itself

- Gross Weight = the full can (soda + can)

These terms apply directly to shipping too. Whether you’re moving airfryers, furniture, or gym apparel—every shipment has net, tare, and gross weight.

Definitions:

- Net Weight: The weight of the goods only, without any packaging, pallets, or containers.

- Tare Weight: The weight of the packaging or container only—empty.

- Gross Weight: The total weight of the goods including packaging, pallets, and containers.

These weights are essential for calculating shipping costs, determining load limits, and filling out legal documents like bills of lading and customs invoices.

Why Accurate Weight Calculation Matters in Shipping

Ignoring these numbers? That’s like driving blind on a highway. Here’s why accurate weight matters:

1. Freight Costs Depend on Weight

Shipping companies charge based on gross weight or volumetric weight (whichever is higher). If your gross weight is incorrect, you’ll get hit with surprise fees.

2. Customs Clearance Requires Precision

Many customs authorities inspect weight declarations. Mistakes can cause:

- Port delays

- Rejected paperwork

- Extra inspections or fines

3. Vehicle & Load Safety

Overloading a truck, ship, or plane based on wrong weight data can violate safety regulations—and even get your cargo rejected.

4. Inventory & Warehouse Planning

Knowing your net weight helps you plan for inventory control, shelf capacity, and warehouse stacking.

5. Financial Reporting & Cost Accounting

For manufacturers and retailers, net weight affects per-unit cost breakdown, profit margin, and tax planning.

Net Weight Explained

Let’s dig into net weight first.

What Is Net Weight?

Net weight is the actual weight of the product itself, without any packaging, filler, or containers.

For example:

- A box of dumbbells may have a net weight of 10 kg

- A 5-liter bottle of olive oil might weigh 5.2 kg net

This is the number you care about when:

- Charging for product-only pricing

- Doing customs declarations (for many countries, duties are based on net weight)

- Comparing supplier quotes on raw materials

What Net Weight Doesn’t Include:

- Cardboard boxes

- Bubble wrap

- Plastic film

- Pallets

- Straps or outer containers

Pro Tip: Always confirm whether your supplier quotes product weights as net or gross—don’t assume!

Tare Weight Explained

Now let’s look at tare weight—a critical piece of the shipping equation that many first-time importers overlook.

What Is Tare Weight?

Tare weight refers to the weight of the packaging materials and containers used to transport your goods, but not the goods themselves.

Think of it like this:

- You’re shipping 1,000 ceramic mugs.

- The mugs are packed in boxes, which are loaded onto wooden pallets, wrapped with plastic film.

- All of this—boxes, pallets, plastic—is tare weight.

Common Components That Contribute to Tare Weight:

- Cardboard boxes and inserts

- Plastic bags or film

- Wooden or plastic pallets (usually 10–25 kg each)

- Plastic straps or zip ties

- Crates or metal drums

- Shipping cartons

Real-World Example:

Let’s say you’re importing stainless steel water bottles:

- Each bottle weighs 0.4 kg (net)

- Each is placed in a printed box (0.1 kg)

- 20 bottles per shipping carton (carton = 2.5 kg)

- Each pallet carries 20 cartons and weighs 22 kg

In this case:

- Net Weight (20 bottles) = 0.4 kg × 20 = 8 kg

- Tare Weight (box + carton + pallet) = (0.1 kg × 20) + 2.5 kg + 22 kg = 26.5 kg

- Gross Weight = 8 kg (net) + 26.5 kg (tare) = 34.5 kg

This breakdown is crucial when completing your shipping documentation and calculating your freight rate.

Pro Tip: Ask your supplier for a packing list that includes detailed tare weights—not just total weight.

Gross Weight Explained

Now we come to the final piece: gross weight—the number most logistics companies care about.

What Is Gross Weight?

Gross weight is the total weight of everything being shipped—product + packaging + pallets + crates + everything.

This number is critical for:

- Freight pricing

- Booking cargo space

- Customs clearance

- Vehicle load limits

Gross Weight Formula:

Gross Weight = Net Weight + Tare Weight

If you’re using a freight forwarder or working with platforms like Alibaba or Made-in-China, this is the number they’ll ask for.

Why It Matters So Much:

- Shipping Charges:

Freight companies often charge by gross weight or dimensional (volume) weight—whichever is greater. Even small tare weight changes can affect cost. - Customs Documents:

Bills of lading, packing lists, and commercial invoices must list gross weight accurately. Customs authorities may inspect or re-weigh your cargo. - Safety Regulations:

Trucks, aircraft, and ships have legal limits for total weight. Incorrect declarations can cause fines or even refusal to transport.

Real Example:

You’re importing 500 airfryers packed in foam and cardboard boxes on 10 pallets.

- Net weight per unit = 3.5 kg

- Tare per unit (box + inserts) = 1.2 kg

- Pallet + straps = 25 kg per pallet

- Total product net = 500 × 3.5 = 1,750 kg

- Total unit packaging = 500 × 1.2 = 600 kg

- Pallet tare = 10 × 25 = 250 kg

- Total Tare = 600 + 250 = 850 kg

- Gross Weight = 1,750 + 850 = 2,600 kg

Even small packaging changes can save thousands in shipping fees when scaled.

How to Calculate Each Weight with Formulas

Now that you understand the differences, here are the formulas you need:

Net Weight Formula:

Net Weight = Total Product Weight (excluding packaging)

Tare Weight Formula:

Tare Weight = Total Weight of All Packaging + Pallets + Crates

Gross Weight Formula:

Gross Weight = Net Weight + Tare Weight

Example Scenario:

You’re shipping:

- 100 gym leggings

- Each pair weighs 0.35 kg (net)

- Individual polybag = 0.05 kg

- 25 units per carton, carton = 1.5 kg

- 4 cartons on one 20 kg pallet

Calculations:

- Net = 0.35 × 100 = 35 kg

- Tare (polybags) = 0.05 × 100 = 5 kg

- Tare (cartons) = 1.5 × 4 = 6 kg

- Tare (pallet) = 20 kg

- Total Tare = 5 + 6 + 20 = 31 kg

- Gross Weight = 35 + 31 = 66 kg

Tare Weight in Air vs. Sea Freight

Shipping by air and sea involves vastly different logistics—and tare weight plays a significant role in both.

1. Sea Freight (FCL and LCL)

- FCL (Full Container Load):

You rent the whole container (20ft, 40ft, or 40HQ). The tare weight of the container itself is added to your gross shipment weight. Container TypeTypical Tare Weight20 ft standard~2,200–2,400 kg40 ft standard~3,800–4,000 kg40 ft high cube~3,900–4,200 kg These weights must be declared accurately in your shipping documents to avoid container overloading. - LCL (Less than Container Load):

Your goods share space with others. The tare includes your packaging and any shared pallets, but not the full container. LCL shipments are billed based on CBM (Cubic Meters) or weight—whichever is greater. Packaging strategy here is crucial.

2. Air Freight

Airlines are extremely weight-sensitive. Tare weight is a key factor because:

- Airlines charge based on actual weight or volumetric weight

- Heavier packaging = higher shipping fees

Air cargo packaging includes:

- Carton boxes

- Foam inserts

- Pallets (if required)

- Plastic wrap or netting

Tip: For air shipments, use lightweight materials like honeycomb cardboard and reduce excess filler wherever possible.

How Incorrect Weight Affects Shipping & Customs

Getting your shipping weights wrong isn’t just an inconvenience—it can cost you serious money and time.

Here’s how:

1. Extra Charges from Freight Forwarders

If your gross weight is off by even 50 kg, your freight quote could be re-rated, costing you hundreds more.

2. Customs Clearance Issues

If customs finds a mismatch between declared and actual weights:

- They may delay or detain your shipment

- You may face penalties or higher duties

- Worst case? Cargo is returned or destroyed

3. Inaccurate Inventory

Miscalculating net weight leads to:

- Incorrect stock value

- Misaligned financial records

- Unreliable profit/loss projections

4. Warehouse Handling Problems

Underestimating gross weight can:

- Damage warehouse equipment

- Result in dropped or unsafe pallets

- Cause incorrect shelving or stacking decisions

One factory shipping air purifiers misdeclared gross weight, resulting in an extra $1,400 in airfreight costs—plus a 3-day customs delay.

Where to Find Weight Information

You don’t always need to measure everything yourself. Here’s where to find reliable data:

- Product Datasheets or Specifications

Manufacturers often list net weights on their product spec sheets. - Packaging Designs

If you have your own packaging made, the box supplier can provide the weight. - Previous Shipping Records

Bills of lading or packing lists from past shipments will show gross weights. - Weighing Equipment

- Pallet scales

- Floor scales

- Hanging or crane scales

- Truck weighbridges for full-container verification

- Your Supplier or Sourcing Agent

Ask them to include a full breakdown of net, tare, and gross weight on your packing list or invoice.

Gross Weight on Commercial Invoices and Packing Lists

Shipping documents must clearly state weights. Here’s how to present them correctly:

| Document | What It Must Include |

|---|---|

| Commercial Invoice | Net weight, gross weight, unit weight (if needed) |

| Packing List | Quantity per carton, carton weight, pallet info |

| Bill of Lading (BOL) | Total gross weight of shipment |

| Airway Bill | Net and chargeable weight |

| Customs Declaration | Often based on net weight + HS code |

Pro Tip: Always double-check that all weights match across your documents. Inconsistencies can trigger customs inspection or shipment holds.

Tools & Equipment to Measure Weight Accurately

Want to keep things precise and professional? Here are some tools to invest in or ask your supplier to use:

1. Platform Scales

- Perfect for weighing bulk cartons or pallets

- Digital display with high precision

- Often used in factories and fulfillment centers

2. Pallet Weighers

- Specifically designed to weigh loaded pallets

- Useful for large-scale exporters

3. Portable Weighing Scales

- For smaller packages

- Battery-operated, easy to carry

4. Truck Weighbridges

- Full container or truck weight measurement

- Used in shipping yards and warehouses

Many Chinese manufacturers already use these tools. Just ask for a weighing report or video if you want confirmation.

How Simoosourcing Helps with Weight and Packing Accuracy

If you’re not based in China, verifying packing weight and shipment accuracy can feel like a black hole. That’s where Simoosourcing becomes an invaluable partner—especially for new importers or fast-scaling brands.

Here’s How They Help:

1. Packing List Verification

Simoosourcing checks each supplier’s packing list to ensure:

- Net weight matches product specs

- Tare items (boxes, pallets) are listed correctly

- Gross weight is calculated with no missing components

They’ll cross-verify weight details against factory estimates and catch errors before they affect freight booking or customs declarations.

2. On-Site Weighing and QC Inspections

They can physically visit the factory or warehouse to:

- Weigh sample cartons or pallets

- Compare listed vs actual weights

- Check load balance and stacking safety

This protects you from suppliers misreporting weights to reduce shipping costs—or worse, manipulating freight documents.

3. Accurate Freight Estimation

Simoosourcing works directly with trusted freight forwarders to:

- Get accurate volumetric vs gross weight charges

- Avoid unexpected fees at destination

- Book the best transport method based on your weight class and budget

4. Optimization Advice

If you’re paying too much in tare weight (heavy boxes, inefficient pallet loading), they’ll recommend:

- Better packaging materials

- Smarter product arrangement

- Shrink-wrap alternatives

- Lightweight inner boxes

Their insights can help reduce your total shipping cost by 10–20% or more, depending on volume.

If you’ve ever been burned by a supplier sending “heavier-than-promised” shipments, you’ll appreciate how Simoosourcing simplifies weight management and ensures accuracy from day one.

Tips for Reducing Tare Weight and Saving on Freight

Tare weight can sneak up on your shipping bill. Here are smart ways to keep it low without compromising product protection.

1. Choose Lightweight Packaging Materials

Swap out:

- Thick cardboard for corrugated fiberboard

- Foam for air pillows

- Plastic trays for molded pulp or honeycomb paper

Even reducing just 0.5 kg per unit adds up when shipping thousands.

2. Consolidate Cartons Where Possible

Instead of 10 small cartons, ship 2 larger ones. It:

- Reduces packaging waste

- Lowers per-unit tare weight

- Saves warehouse handling time

3. Use Reusable or Returnable Containers

If working with a repeat manufacturer or logistics provider, ask about:

- Foldable plastic totes

- Reusable crates

- Stackable bins

Initial investment is higher, but long-term savings can be significant.

4. Rethink Pallet Type and Usage

Standard wooden pallets can weigh 15–25 kg each. Try:

- Pressed wood or fiber pallets (~10 kg)

- Recyclable plastic pallets (light and clean)

- No-pallet shipping with floor loading (only for sturdy products)

5. Optimize Layout with 3D Packing Tools

Tools like CargoWiz or PackApp simulate how to best load containers, reducing:

- Unused space

- Number of cartons

- Load imbalances

Less wasted space = fewer pallets = lower tare and gross weight.

Reminder: Always confirm with your freight forwarder or customs agent before switching packing methods. Some changes may require updated safety or compliance documentation.

Read This Review Before You Ship: Common Mistakes to Avoid

Let’s recap the biggest errors importers make when dealing with shipping weights:

❌ Mistake #1: Confusing Net and Gross Weight

Solution: Use separate lines on all documents. Triple-check definitions with your supplier.

❌ Mistake #2: Ignoring Tare in Freight Quotes

Solution: Always calculate total shipment weight including cartons, pallets, and wraps.

❌ Mistake #3: Overloading Containers

Solution: Ask for container tare weight and max capacity. Don’t guess—get the specs.

❌ Mistake #4: Using Outdated Packing Data

Solution: If you update your product design or packaging, reweigh everything. Don’t rely on old weights.

❌ Mistake #5: Not Auditing Supplier Data

Solution: Have your agent (like Simoosourcing) verify weight at origin. Small discrepancies scale into big costs.

By avoiding these mistakes, you save money, reduce risks, and keep your supply chain running smoothly.

Conclusion & Key Takeaways

Whether you’re shipping kettlebells, airfryers, gym apparel, or any other product—knowing how to accurately calculate net, gross, and tare weight is essential.

It’s not just about paperwork. It affects:

- Shipping fees

- Customs clearance

- Inventory control

- Profit margins

Here’s a quick recap:

- Net Weight = Product only

- Tare Weight = Packaging and container only

- Gross Weight = Net + Tare

- Always declare accurate gross weight to avoid fines or shipment delays

- Use tools, weigh regularly, and verify supplier-provided weights

- Partner with Simoosourcing to ensure total accuracy from production to delivery

Master your shipping weights—and you’ll master your logistics.

FAQs About Measure Gross Weight for a Shipment

1. Why is tare weight important in shipping?

Tare weight affects gross weight, which determines shipping costs and compliance. Ignoring it leads to unexpected charges and customs issues.

2. What is the best way to measure gross weight for a shipment?

Use industrial platform or pallet scales. If shipping full containers, use a weighbridge or ask your freight forwarder to verify.

3. Can packaging weight be reduced without damaging the product?

Yes. Lightweight, durable alternatives like honeycomb board, molded pulp, or foam-free designs can protect your goods and cut tare weight.

4. What happens if I declare the wrong gross weight?

You may face penalties, re-rating of freight charges, shipment delays, or customs holds. In severe cases, shipments may be returned or destroyed.

5. How does Simoosourcing help with weight accuracy?

They check weight breakdowns, inspect packing, confirm actual vs stated values, and help you avoid misdeclared weight risks in both sea and air freight.