How Does Nike ‘Really’ Manufacture Their Products in 2025?

Introduction to Nike’s Manufacturing Process

If you’ve ever asked, “How does Nike ‘really’ manufacture their products?”—you’re not alone. With more than 1,000 suppliers and over 30 countries involved, Nike’s global production network is as vast as it is secretive. While the brand markets innovation and performance, many consumers and critics want to know what’s really happening behind the Swoosh.

Nike’s supply chain includes product design, global sourcing, contract manufacturing, and advanced technology integration. But behind the scenes, there’s a complex world involving labor ethics, environmental impact, and competitive secrecy that shapes how each pair of sneakers ends up on your feet.

Let’s dig into how Nike truly operates from sketchbook to shoebox.

Table of Contents

Why the Question “How Does Nike Really Manufacture Their Products?” Matters

Understanding how Nike manufactures its goods gives insight into broader themes like:

- Ethical labor practices

- Environmental sustainability

- Global economic impact

- Brand responsibility

Today’s consumers want transparency, and Nike has responded—albeit selectively. In a market flooded with fast fashion and mass production, Nike’s manufacturing model is both a benchmark and a target of scrutiny.

Overview of Nike’s Global Supply Chain

Nike doesn’t own the majority of its production facilities. Instead, it works with more than 500 third-party factories spread across Asia, Latin America, and Eastern Europe. These factories are contracted under strict quality and compliance guidelines—but Nike maintains a level of distance that has drawn criticism and applause alike.

Where Are Nike Products Made?

List of Major Manufacturing Countries

As of 2025, Nike’s main manufacturing hubs include:

- Vietnam – Over 40% of Nike’s footwear

- Indonesia – Significant production of sneakers and apparel

- China – Footwear, accessories, and high-tech prototypes

- India – Apparel and accessories

- Thailand, Mexico, and Brazil – Specialty and regional items

Breakdown of Regional Operations

Nike breaks its operations into regions—North America, EMEA (Europe, Middle East, Africa), Greater China, and APLA (Asia Pacific Latin America). Each region handles its sourcing, logistics, and distribution, optimizing efficiency and tailoring products to local demands.

Step-by-Step Breakdown of Nike’s Manufacturing Process

1. Product Design and Innovation

Everything begins at Nike’s headquarters in Beaverton, Oregon, where hundreds of designers and engineers conceptualize new products. Nike uses:

- CAD software for prototyping

- 3D printing for rapid sampling

- Athlete data to inform function

Nike’s Innovation Kitchen is where experimental products like Flyknit, Air technology, and React foam begin.

2. Sourcing of Raw Materials

Nike’s sourcing includes:

- Natural rubber from Southeast Asia

- Synthetic fabrics like polyester from petrochemical producers

- Flyknit yarns (often recycled)

- Leather (certified gold/silver by the Leather Working Group)

Nike vets suppliers for sustainability, ethical sourcing, and cost-effectiveness.

3. Outsourcing to Contract Factories

Once designs and materials are finalized, they’re sent to independent factories—most located in Vietnam, Indonesia, and China.

- Nike issues detailed blueprints and performance specs

- Factories handle cutting, stitching, assembly

- Supervisors and Nike quality control teams are often present

4. Manufacturing and Assembly Process

The manufacturing line for a Nike shoe involves:

- Cutting upper material

- Sewing components

- Attaching the midsole

- Adding the outsole

- Branding and final touches

- Packaging

This is largely done by hand, but automation is increasing in high-tech facilities.

5. Quality Control and Testing

Before shipping, each product undergoes:

- Visual inspections

- Stress testing

- Material checks

- Performance trials (on athletes or mannequins)

Nike ensures that every product aligns with its reputation for durability and style.

Inside Nike’s Factories

Factory Work Conditions

Nike has come a long way from the controversies of the 1990s. Today, the company insists on maintaining safe, regulated working environments in its contract factories. This includes:

- Limiting working hours

- Ensuring minimum wage compliance

- Providing safe equipment and environments

Nike conducts regular audits through internal teams and third-party organizations to monitor factory performance.

Labor Practices and Ethical Concerns

Despite improvements, Nike still faces scrutiny. Critics argue that in countries like Vietnam or Indonesia:

- Workers may still face low wages relative to living costs

- Union activity is sometimes discouraged

- Some factories depend heavily on temporary contracts to avoid long-term labor commitments

Nike responds with initiatives like the Supplier Responsibility Program, which enforces compliance on child labor, forced labor, and discrimination.

Use of Technology and Automation

Nike is increasingly embracing automation and digital manufacturing. In newer factories, you’ll find:

- Robotic cutting machines for precision

- RFID tracking to monitor production

- Automated packaging lines

- Smart sensors to monitor worker efficiency and safety

This technology reduces human error, improves consistency, and accelerates production timelines.

Sustainability in Nike’s Manufacturing

Nike’s Move to Circular Manufacturing

Nike aims to “close the loop” in its supply chain. This means designing products that can be recycled, reused, or returned into the manufacturing process.

The Nike Grind Program converts old shoes and manufacturing waste into material used in:

- Track surfaces

- Playground flooring

- New product soles

Use of Recycled Materials and Waste Reduction

Nike’s signature sustainability initiatives include:

- Flyknit technology – drastically reduces fabric waste by knitting the upper in one piece

- Nike Air soles – now made with over 50% recycled materials

- Recycled polyester – used in performance wear from plastic bottles

In 2023 alone, Nike claimed to have diverted over 1 billion plastic bottles from landfills into their products.

Environmental Certifications and Targets

Nike’s 2025 goals focus on:

- 100% renewable energy across global operations

- 50% carbon reduction per unit

- Zero waste to landfill from key suppliers

The brand also aligns with the Science-Based Targets initiative (SBTi) and reports its progress in annual Impact Reports.

Real Stories: Worker Insights and Community Impact

Employee Testimonies

Many employees in Nike’s contract factories report:

- Improvements in facilities and working conditions

- Access to training programs and healthcare

- Opportunities for career advancement

However, advocacy groups argue that Nike’s factory audits don’t always catch abuse and more transparency is needed.

Impact on Local Communities

Nike’s operations bring:

- Jobs to developing regions

- Investments in local infrastructure

- Partnerships with local education and wellness NGOs

Programs like the Nike Foundation and Girl Effect have impacted millions of lives in manufacturing countries.

Nike’s Transparency Initiatives

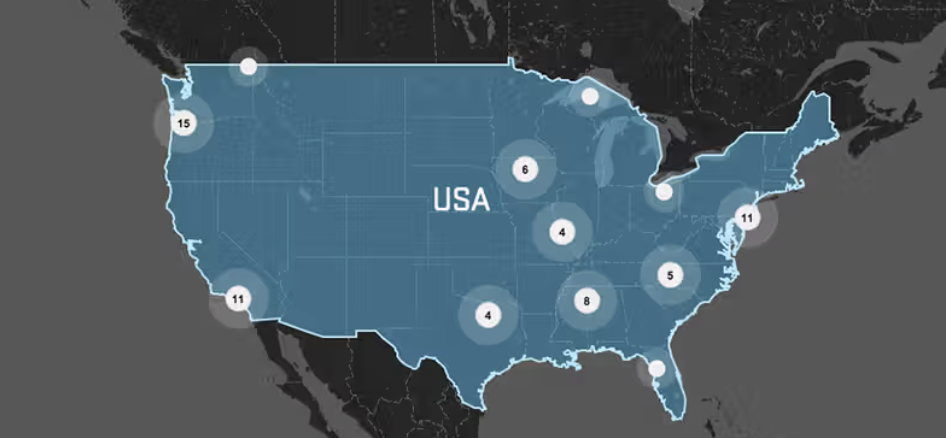

The Nike Manufacturing Map

To build trust, Nike launched its interactive manufacturing map, listing:

- Factory locations

- Types of goods produced

- Employee count

- Factory certifications

This map allows anyone to trace where Nike products are made, reinforcing its commitment to openness.

Supplier Code of Conduct

Nike’s Supplier Code of Conduct outlines standards in:

- Fair labor practices

- Health and safety

- Environmental responsibility

- Anti-corruption

Factories that fail audits risk losing Nike’s business, a policy that’s enforced with growing consistency.

Controversies Around Nike’s Manufacturing

Historical Issues with Sweatshops

In the 1990s, Nike became the poster child for unethical manufacturing due to:

- Child labor allegations

- Unsafe factory conditions

- Suppression of worker rights

This backlash led to widespread protests, boycotts, and a major PR crisis.

Improvements Since the 1990s

Since then, Nike has:

- Partnered with NGOs to develop fair labor standards

- Released annual Corporate Social Responsibility (CSR) reports

- Improved wage transparency and gender equality across its factories

According to external audits, over 80% of Nike’s factories now meet or exceed labor compliance standards.

Current Criticism and Brand Response

Despite progress, watchdogs still challenge Nike over:

- Over-reliance on low-cost labor

- Lack of third-party verification

- Greenwashing in marketing efforts

Nike counters this by highlighting measurable improvements, third-party audit results, and publishing sustainability reports through organizations like CDP and SBTi.

How Nike Ensures Product Quality

Material Testing and Prototyping

Nike invests in rigorous R&D testing:

- Materials are exposed to stress, heat, and moisture

- Products are tested using wear simulators and athlete feedback

- Prototypes undergo hundreds of revisions before approval

Field Performance Evaluation

Before launch, products are:

- Tested by athletes

- Evaluated in real-world conditions

- Adjusted based on feedback from sponsored professionals and ambassadors

This ensures each Nike shoe or jersey lives up to the company’s performance standards.

Table: Summary of Nike’s Manufacturing Steps

| Stage | Details |

|---|---|

| Design & Innovation | CAD modeling, athlete insights, 3D prototyping |

| Material Sourcing | Global procurement (rubber, leather, synthetics) |

| Factory Assignment | Contracts with certified third-party manufacturers |

| Production | Cutting, stitching, assembly—partially automated |

| Quality Control | Visual checks, stress testing, athlete feedback |

| Sustainability Checks | Recycled content, waste reduction, circular design |

| Shipment & Distribution | Global logistics to regional warehouses and stores |

Conclusion

So, how does Nike ‘really’ manufacture their products? It’s a mix of high-tech innovation, outsourced labor, sustainability pledges, and ongoing controversy. Nike has undoubtedly transformed from a brand criticized for sweatshops to a global leader in sustainable manufacturing practices—but not without flaws.

The company’s evolution shows the complexities of global production, especially when balancing profit, ethics, and performance. Whether you’re a fan of Nike or a conscious consumer doing your research, knowing the real story behind your sneakers adds meaning to every step you take.

FAQs About Nike’s manufacturing

1. Are Nike products still made in sweatshops?

Nike has improved oversight dramatically, but concerns persist, especially in less regulated factories.

2. How sustainable is Nike’s manufacturing today?

Nike leads in recycled materials and waste reduction, though critics argue it can do more.

3. Does Nike own its factories?

No. Nike outsources to over 500 independently owned factories worldwide.

4. Where does Nike get its raw materials?

From certified suppliers across Asia and South America, with increasing use of recycled content.

5. What technologies does Nike use in production?

Nike uses 3D printing, robotic automation, Flyknit technology, and smart sensors in advanced factories.