How to Use a Product Specification Sheet for Your Sourcing from China?

In the complex and competitive world of global product sourcing, having the right tools at your disposal is non-negotiable.

One of the most underrated yet vital documents in this process is the Product Specification Sheet (also known as a Product Spec Sheet or PSS).

When used correctly, it can be a powerful asset that aligns your expectations with manufacturers, avoids miscommunications, and ensures product quality and compliance.

Below, we dive deep into how to effectively use a Product Spec Sheet for sourcing products from suppliers, especially in international markets like China, Vietnam, and India.

Table of Contents

What is a Product Specification Sheet?

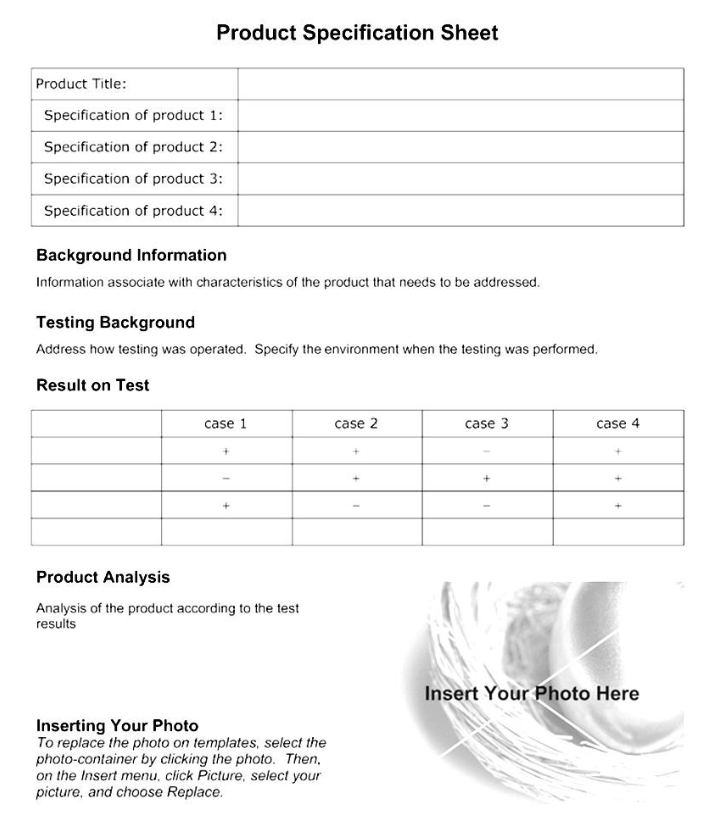

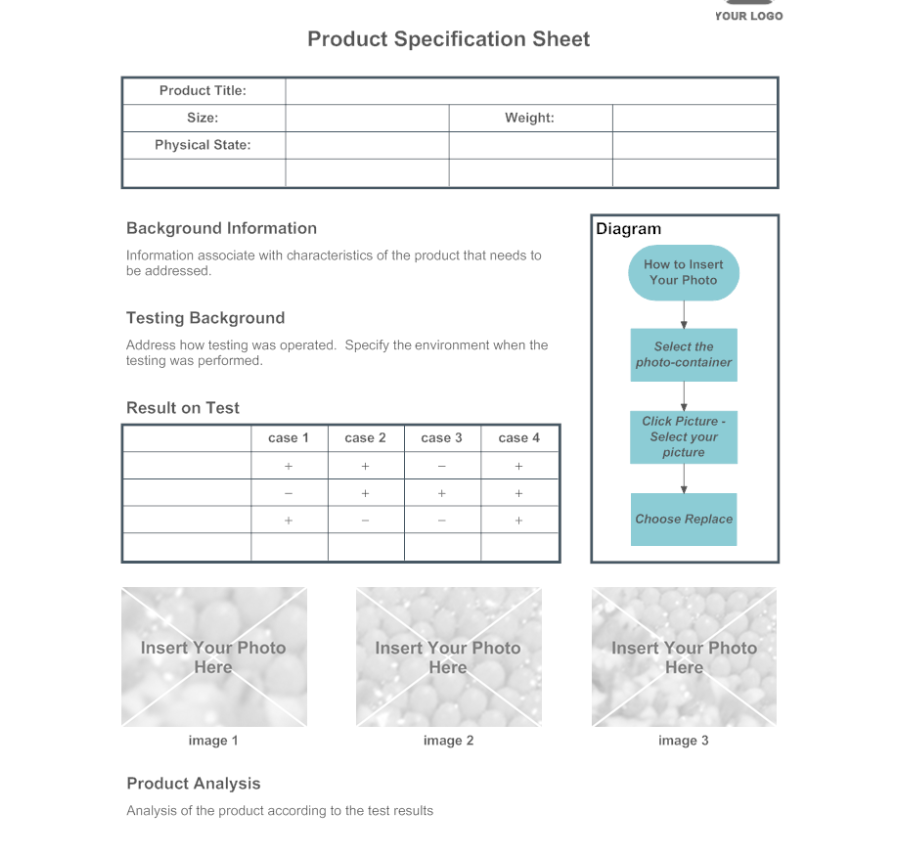

A Product Specification Sheet is a detailed document that outlines all the essential technical and functional aspects of a product. It is not just a sheet of specs—it is your blueprint, your quality control guide, and your negotiation tool.

It typically includes:

- Product Name and Code

- Material Details

- Dimensions and Tolerances

- Colors and Finishes

- Packaging Requirements

- Labeling and Compliance Information

- Functionality Descriptions

- Visual References or Diagrams

- Certification Requirements (e.g., CE, FDA, FCC)

- Quality Standards or Benchmarks

Why a Product Specification Sheet is Critical in Sourcing

When you are sourcing from suppliers—especially overseas manufacturers—clear communication is essential. Language barriers, cultural differences, and production constraints can quickly turn your product vision into something very different.

Using a comprehensive spec sheet:

- Minimizes Errors and Misunderstandings

- Standardizes Product Quality

- Sets Expectations Clearly

- Reduces Disputes During Inspection

- Streamlines Quotation Processes

- Speeds Up Manufacturing Lead Time

How to Create a Professional Product Specification Sheet

1. Define the Core Product Information

Start with the basics, but be accurate. Include:

- Product Title: Use a clear, searchable name.

- Model or SKU Number: Create internal consistency in product tracking.

- Product Category: E.g., Electronics, Apparel, Beauty Tools, etc.

2. List Material and Component Details

Specify exact materials used. If it’s a stainless steel kitchen tool, mention the grade—304, 316, etc. If it’s a cotton T-shirt, mention GSM, cotton origin (e.g., Turkish cotton), and blend ratios.

For components, include:

- Chipset model (for electronics)

- Type of zipper (for garments or bags)

- Battery capacity (for gadgets)

- Paint finish or coating process (for home decor or tools)

3. Mention Product Dimensions and Tolerances

Clearly state:

- Length, Width, Height

- Weight (Net and Gross)

- Tolerances (+/- allowed variation)

Using millimeters (mm) and grams (g) ensures precision, especially when dealing with factories in Asia.

4. Add Color Codes and Finishes

Use Pantone color codes or RAL color standards to avoid ambiguity. Specify finishes like:

- Matte or Glossy

- Anodized or Powder Coated

- Textured or Smooth

Include high-resolution images or diagrams for reference.

Packaging, Labeling & Compliance Details

5. Packaging Requirements

Your spec sheet should specify:

- Individual Packaging Type: Box, polybag, clamshell, etc.

- Carton Dimensions

- Packaging Materials: Recyclable, foam inserts, blister packaging

- Weight per Carton

- Palletization Details if shipping via sea freight

6. Labeling Instructions

Clear labeling is key to customs clearance and retail compliance. Include:

- Country of Origin Label

- Product Barcode (UPC, EAN)

- Safety Warnings

- Brand Logo Placement

- Instruction Manuals or Inserts (mention file format and languages)

Certifications and Legal Compliance

For markets like the EU or USA, mention:

- CE, RoHS, REACH (for EU)

- FCC, FDA, CPSIA (for USA)

- MSDS Sheets for hazardous materials

- REACH declaration

- Import tariff codes (HS Code)

Including these in your product spec sheet shows suppliers that you’re serious about legal and compliance aspects.

How to Share the Product Specification Sheet with Suppliers

Use these tips for effective communication:

- Send the sheet as a PDF to preserve formatting.

- Include CAD drawings or 3D renders if available.

- Use cloud sharing (e.g., Google Drive or Dropbox) for version control.

- Ask suppliers to sign and confirm understanding before production.

- Update the spec sheet as your product evolves—and keep a record of each version.

How to Use the Product Spec Sheet During Production

A Product Spec Sheet isn’t a one-time-use document. It plays an active role in various stages:

Quotation Stage

- Suppliers will use your spec sheet to provide accurate quotes. Without it, you’re likely to receive vague or incomplete pricing.

Sample Review

- Match the sample against your spec sheet. Use it as a checklist to accept or reject samples.

Mass Production

- The manufacturer’s production team will refer to the sheet. Any ambiguity can result in delays or quality issues.

Quality Inspection

- Share the spec sheet with third-party inspectors (like SGS, Bureau Veritas). They will use it as a reference to check conformity before shipment.

How to Use a Spec Sheet in Dispute Resolution

Should a product defect arise or specs not be met, your Product Specification Sheet becomes your legal fallback.

- You can point to exact specifications that were not followed.

- It becomes part of your purchase contract, proving your side of the story.

- If you used trade assurance (like Alibaba), this can be submitted as evidence.

Templates and Tools to Create a Spec Sheet

You don’t need expensive software. Try:

- Google Docs or Sheets – for live collaboration

- Canva or Adobe Illustrator – for design-heavy products

- Notion or Airtable – for dynamic spec management

- MS Word/PDF – for universally readable formats

- Figma or AutoCAD – for technical drawings

Pro Tip: Always keep a version-controlled folder for each product with its latest spec sheet and related documents.

Final Thoughts: Turn Your Spec Sheet Into a Competitive Advantage

Whether you are a sourcing agent, Amazon FBA seller, private label brand, or wholesale importer, using a professional Product Spec Sheet is one of the smartest moves you can make.

It sets the standard for every part of your sourcing journey and makes you look reliable in the eyes of top-tier manufacturers.

Take the time to build one, and you’ll avoid costly mistakes, get better quotes, and build stronger supplier relationships.

Frequently Asked Questions About Product Specification Sheet

❓ What is a Product Specification Sheet (PSS)?

A Product Specification Sheet is a detailed document that outlines all technical, functional, and compliance information about a product.

It includes materials, dimensions, tolerances, color codes, packaging, labeling, and certification requirements. It is essential for aligning expectations with suppliers and ensuring product consistency.

❓ Why is a Product Spec Sheet important in product sourcing?

A spec sheet reduces miscommunication, ensures quality, clarifies compliance needs, and provides a clear reference for production, inspection, and legal protection. It acts as a universal language between you and the supplier.

❓ What should be included in a Product Spec Sheet?

Key elements include:

- Product name/SKU

- Material specifications

- Dimensions and tolerances

- Color codes (Pantone/RAL)

- Packaging requirements

- Labeling details

- Functionality descriptions

- Compliance certifications

- Visual diagrams or sketches

❓ How do I create a Product Spec Sheet?

You can use tools like Microsoft Word, Google Docs, Excel, Canva, or design software like Figma or Adobe Illustrator. Include structured sections for each specification, and always export it as a PDF to maintain formatting when sharing with suppliers.

❓ Can a Product Spec Sheet help reduce product defects?

Yes. By clearly defining the expected product characteristics, suppliers are less likely to make errors during production. It also makes quality inspections more accurate and objective.